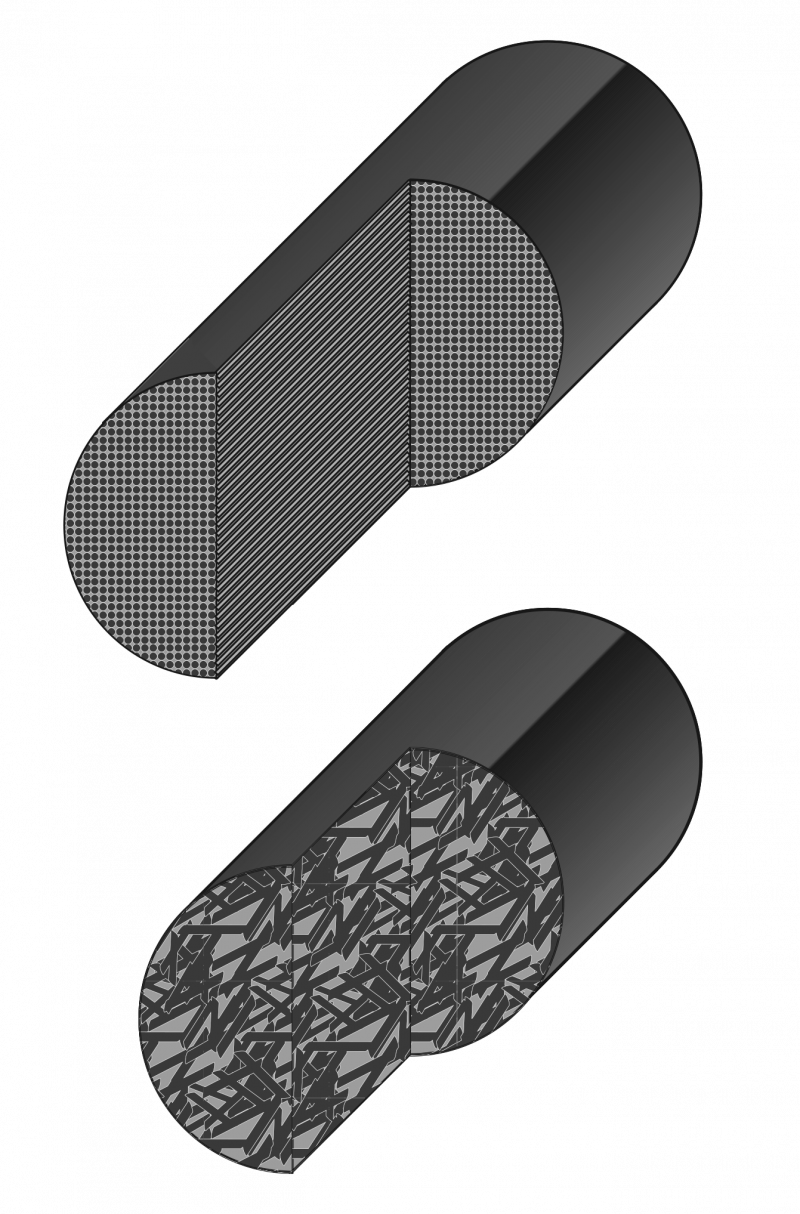

a comparison

Short & Continous Fibers

Short Fiber (FFF) | Continuous Fiber (CFFP) | |

Fiber Length | up to 0,1 mm | Continuous |

Fiber Content | 15 – 30% | up to 60% |

Fiber Orientation | approximately to the print direction | exactly along the print direction |

Strength of the printed part | approx. ~ 100 N/mm² | approx. ~ 1.500 N/mm² |

Fiber Types | Carbon, Glassfaser, Aramid | Carbon, Glasfaser, Aramid and functional fibers like optical fibers or metal wires |

*Values are for guidance only and may vary depending on the final product and customer requirements.

Questions?

Contact me!

Philipp Ropele

Managing Director

Expert in 3D-Printing