More information about composite printing?

Download the case study with all insights now!

MATERIAL COMPARISON

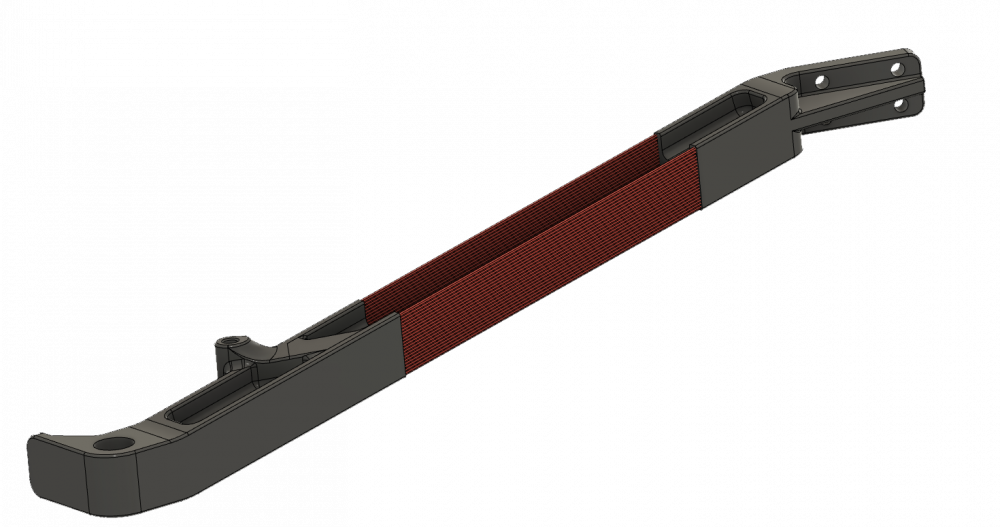

Accelerator pedal | Aluminum | CARBON - PEKK | Improvement |

| Manufacturing type | 5-axis milling | Continuous carbon fiber with FFF | Faster iterations possible |

| Component weight | 90 g | 42 g | + 47% |

| Implementation duration |

Interested? Find more information in our whitepaper. | Same for single piece | |

| Manufacturing costs | - 20% | ||

| Specific tensile strength* | + 472% | ||

Curious?

Download Case Study with all technical specifications now!

Your contact for industrial 3D printing with composites

You have questions?

Contact me!

Nicolai Wampl

Managing Director