Our Goal

Lighter

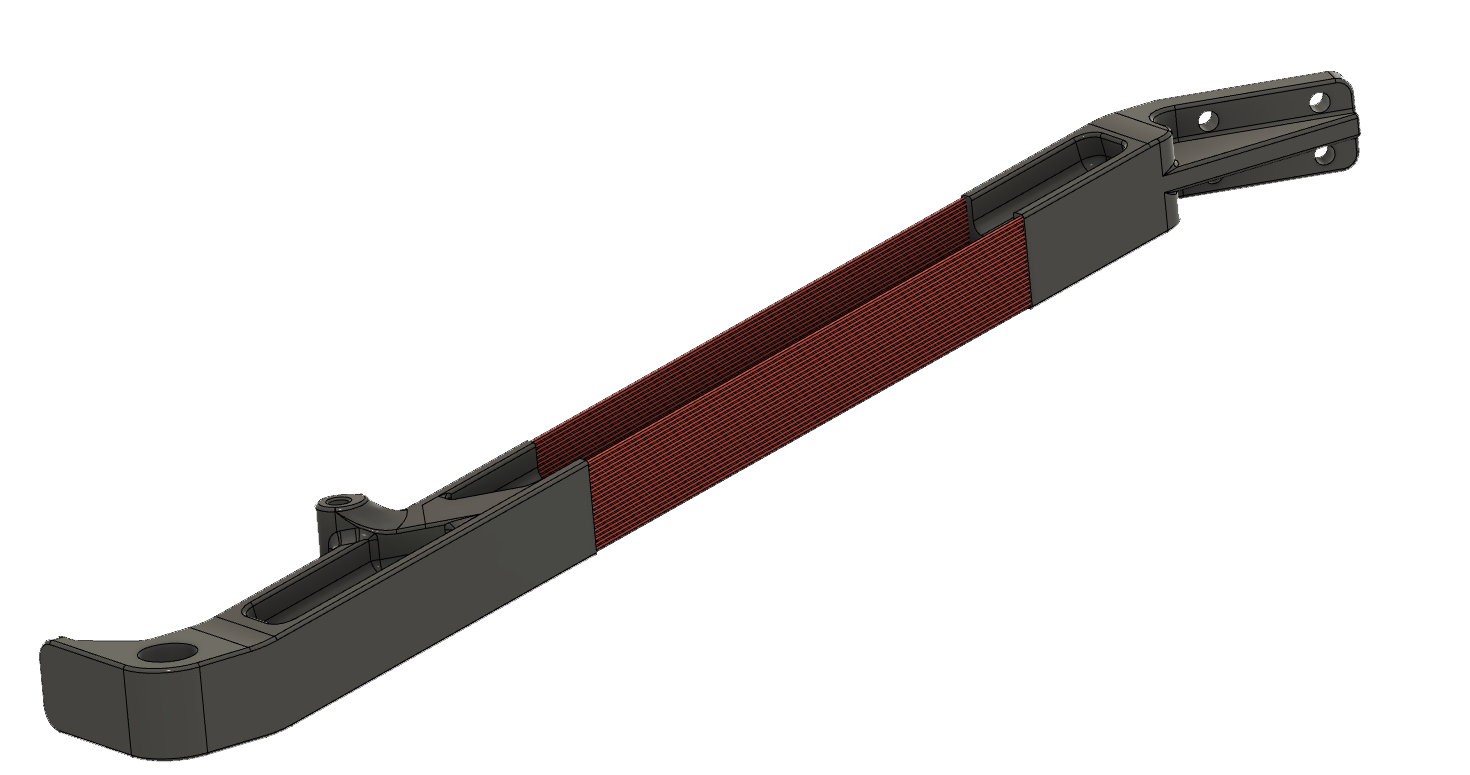

The combination of our CFFP (Collision Free Fiber Placement) Process combined with thermoplastic extrusions 3D printing (FFF), grants new possibilities for lightweight struture.

Place the fibers where you need them!

Smarter

Our tool changing system combines different processes and materials.

Currently it is possible to integrate six tools in one process, which not only allows the production of multi-material parts but also multi-functional parts.

Integrate electrical wires and optical fibers into your parts with our CFFP process.

Stronger

Carbon is characterized by particularly high mechanical strength, especially when forces are applied in the same direction as the fibers.

With our 5-axis gantry system we are starting a new era by enabling fibers to be laid in real 3D- splines, curves or paths in direction of the applied forces.

Testimonial:

Testimonial:

References and Use Cases